ELEMENTS OF J&J

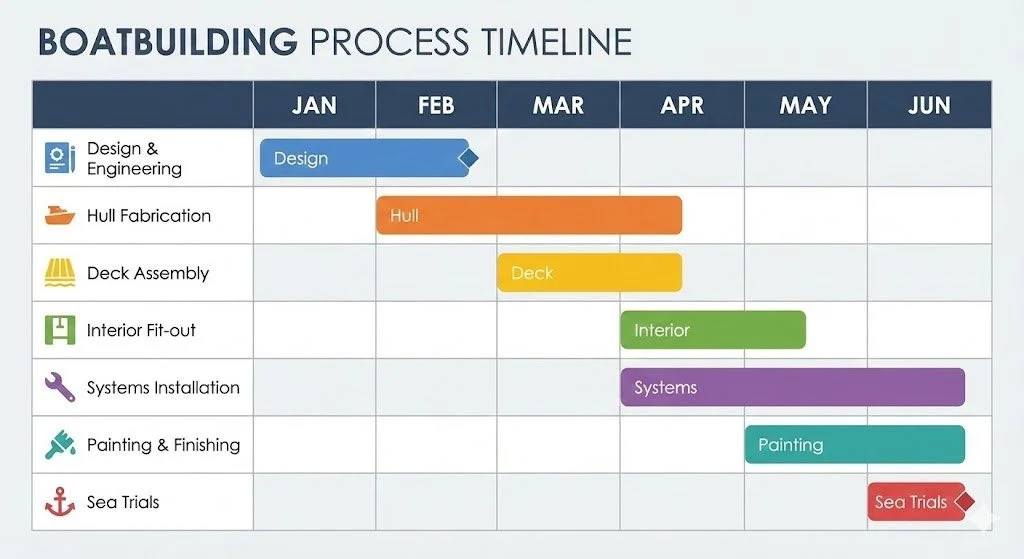

DEVELOPMENT PROCESS

J&J Design unites concept, naval architecture, engineering, production, and branding in a single, integrated process. Every stage is optimised for performance, efficiency, and sustainability, delivering innovative, market-ready solutions in close partnership with boatbuilders.

01/

Preliminary

It is very important that the yard (the client) and J&J have a good understanding of the yard’s qualities and challenges in the current and future markets. In many cases J&J’s neutral and objective view (having intimately worked with 70 yards worldwide) enables to evaluate and directly compare all relevant areas: the products, sales/marketing/branding, production infrastructure, technology, skills and purchasing, including management aspects. Such a benchmark preliminary study gives a good and objective insight into the boatbuilding company within the boating industry and is often requested by the owners (and less frequently by the management…).

02/

Concept

Contains the definition or redefinition of the range where the new model is positioned - or of the new range if a new range is created. The mission, idea and statement of the new product or range. Financial and business aspects. Short definition of the new model.

03/

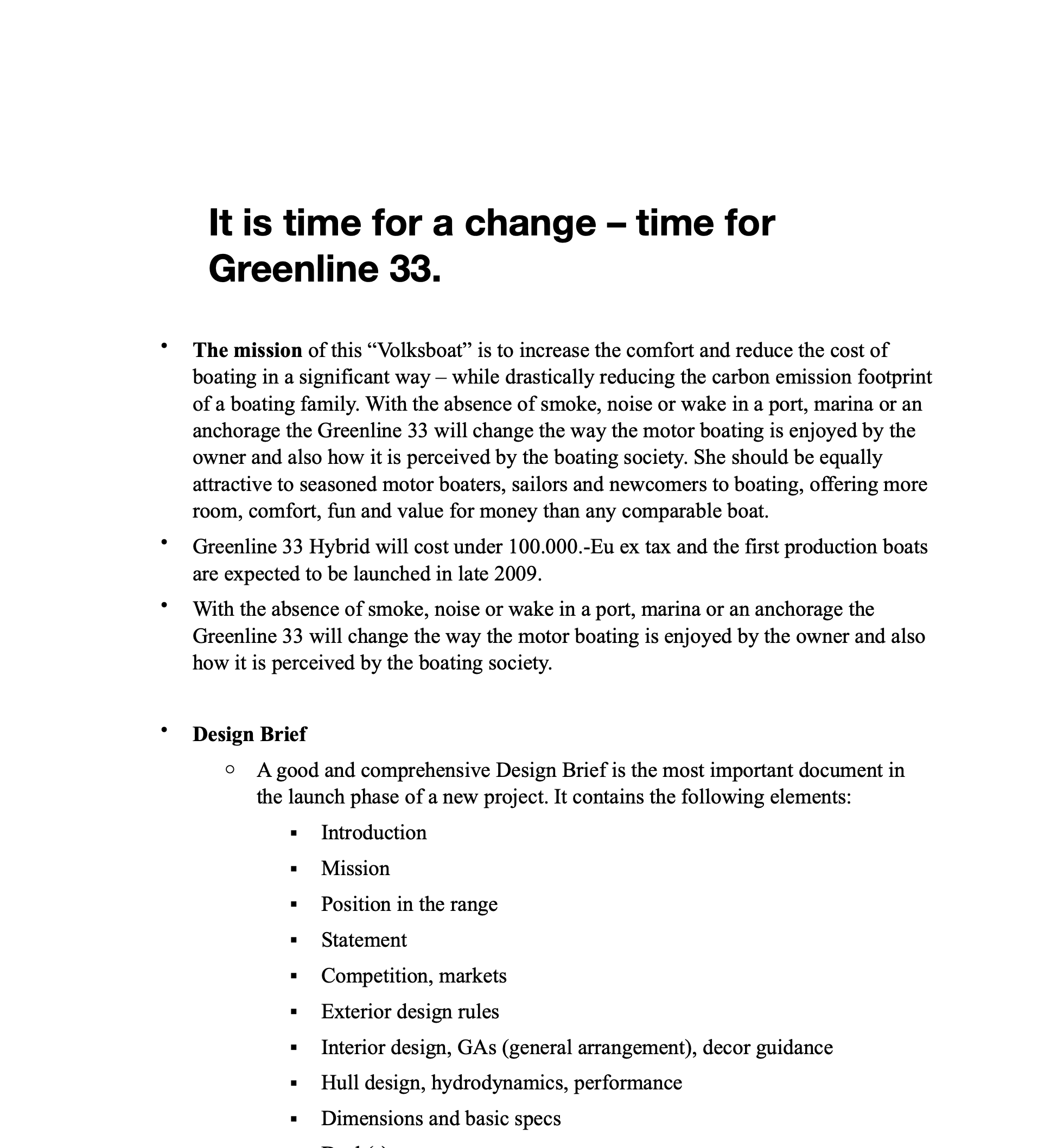

Design Brief

A good and comprehensive Design Brief is the most important document in the launch phase of a new project. It contains the following elements:

-

• Introduction

• Mission

• Position in the range

• Statement

• Competition, markets

• Exterior design rules

• Interior design, GAs (general arrangement), decor guidance

• Hull design, hydrodynamics, performance

• Dimensions and basic specs

• Deck(s) concepts

• Hull and deck gear

• Engine(s), propulsion, steering

• Tanks

• Systems

• Interior, woodwork etc.

• Hydraulics

• HVAC

• Competitors table

• Pricing considerations

• Cost and price structure

• Preliminary BOM and cost structure

• CAPEX, ROI,..

• Production consideration and impact of new model on production structure, capacity and organisation

• Marketing considerations

• Timing

04/

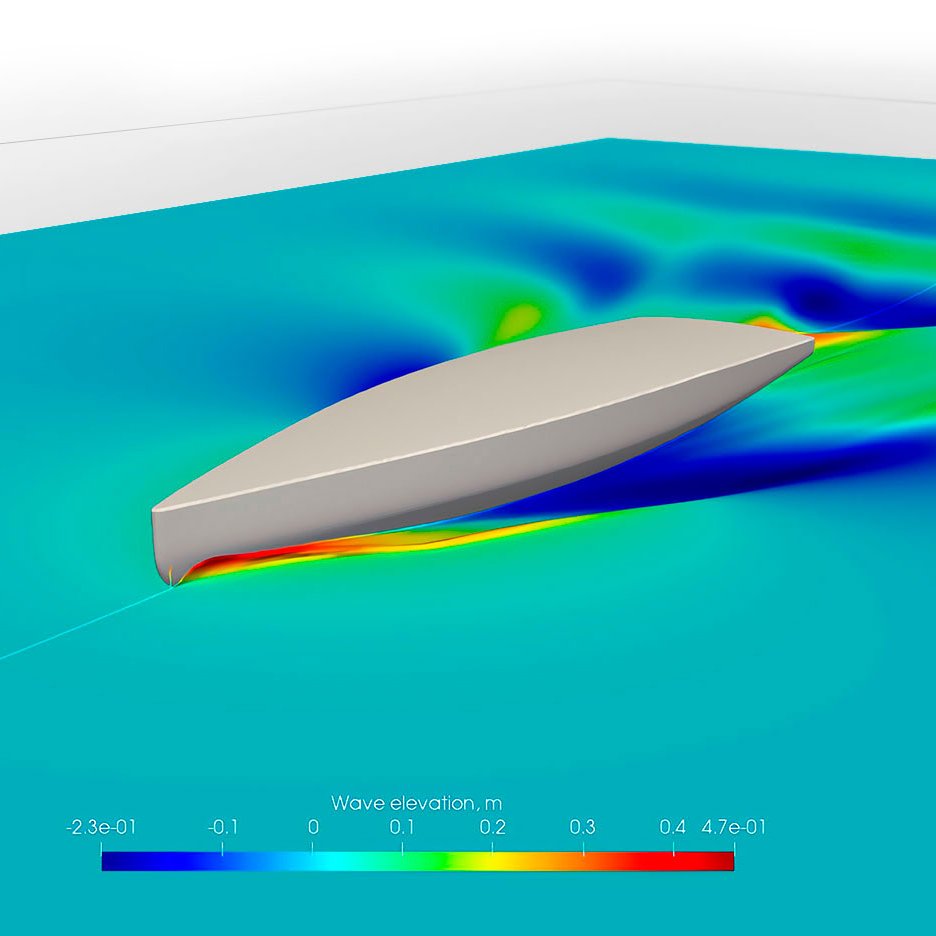

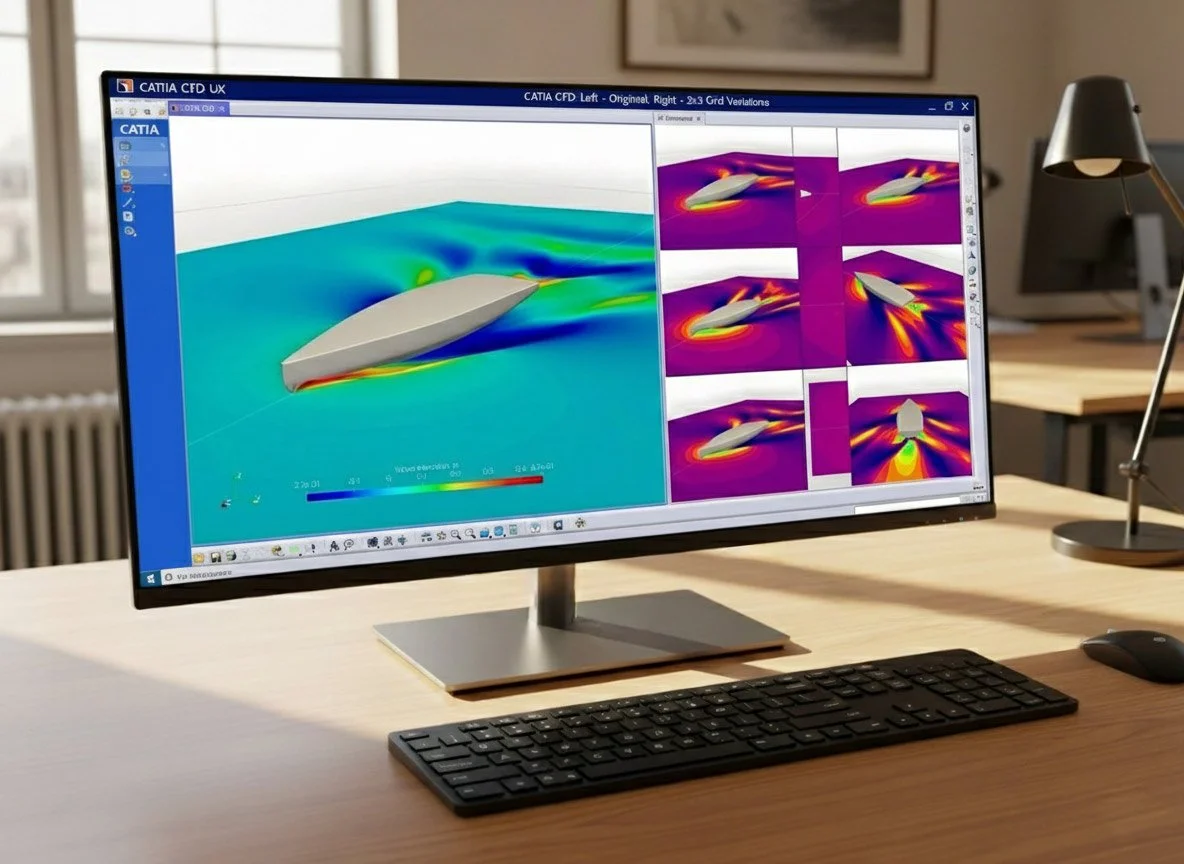

Naval Architecture

The art of a hull design which is safe, stable, easily manoeuvrable, efficient and beautiful is based on correct knowledge and interpretation of scientific data - and experience. More than 75000 boats and yachts based on projects coming from our office give us good understanding of this area. The right 3D geometry of all naval architecture elements is based on CFD studies and/or tank testing data, and on sea-keeping and stability studies. To establish valid prediction of speeds and behaviour a good understanding of the true production weights and options-dependent load case are primordial.

05/

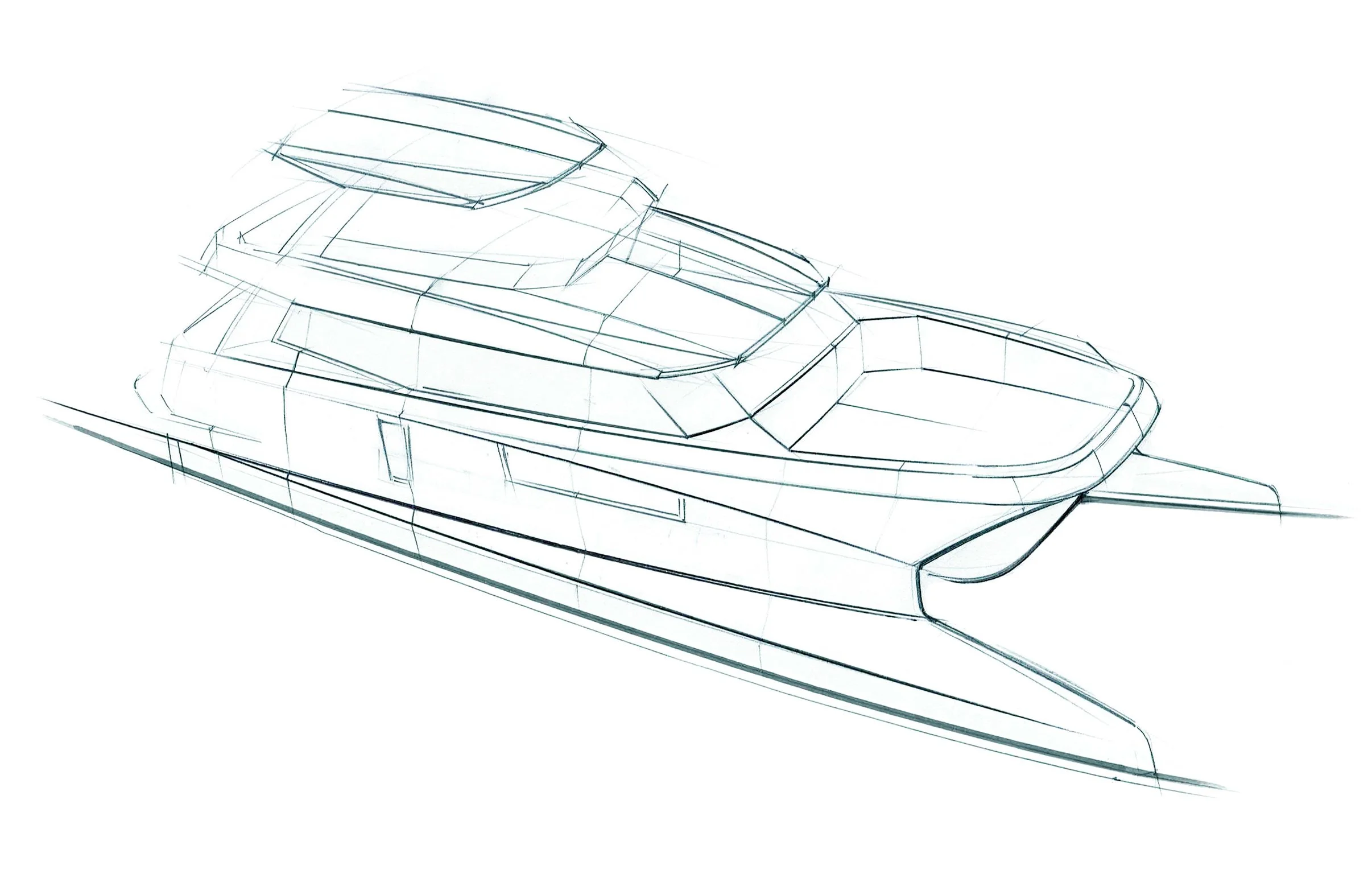

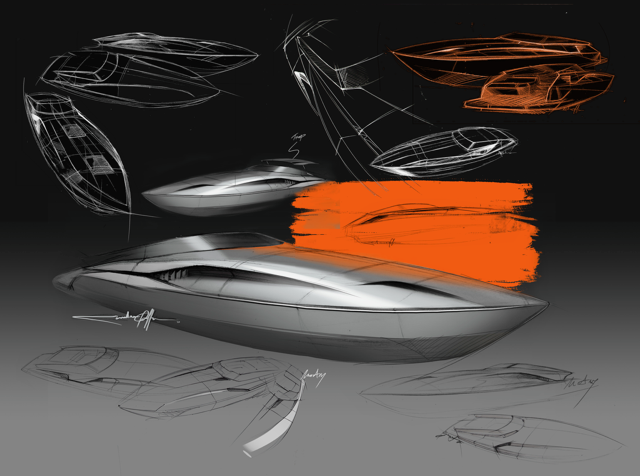

Exterior Design

Conceptual exterior design sketches are typically based on a so called “technical package” to avoid later conflicts with axiomatic conceptual and engineering needs. Then these rough sketches are developed into “aeristic impression” drawings and preliminary 3D models which serve to develop Virtual Reality and scale physical models which allow good evaluation of the work. Later final 3D models and realistic renders are developed, and as needed modified to develop marketing and sales materials.

06/

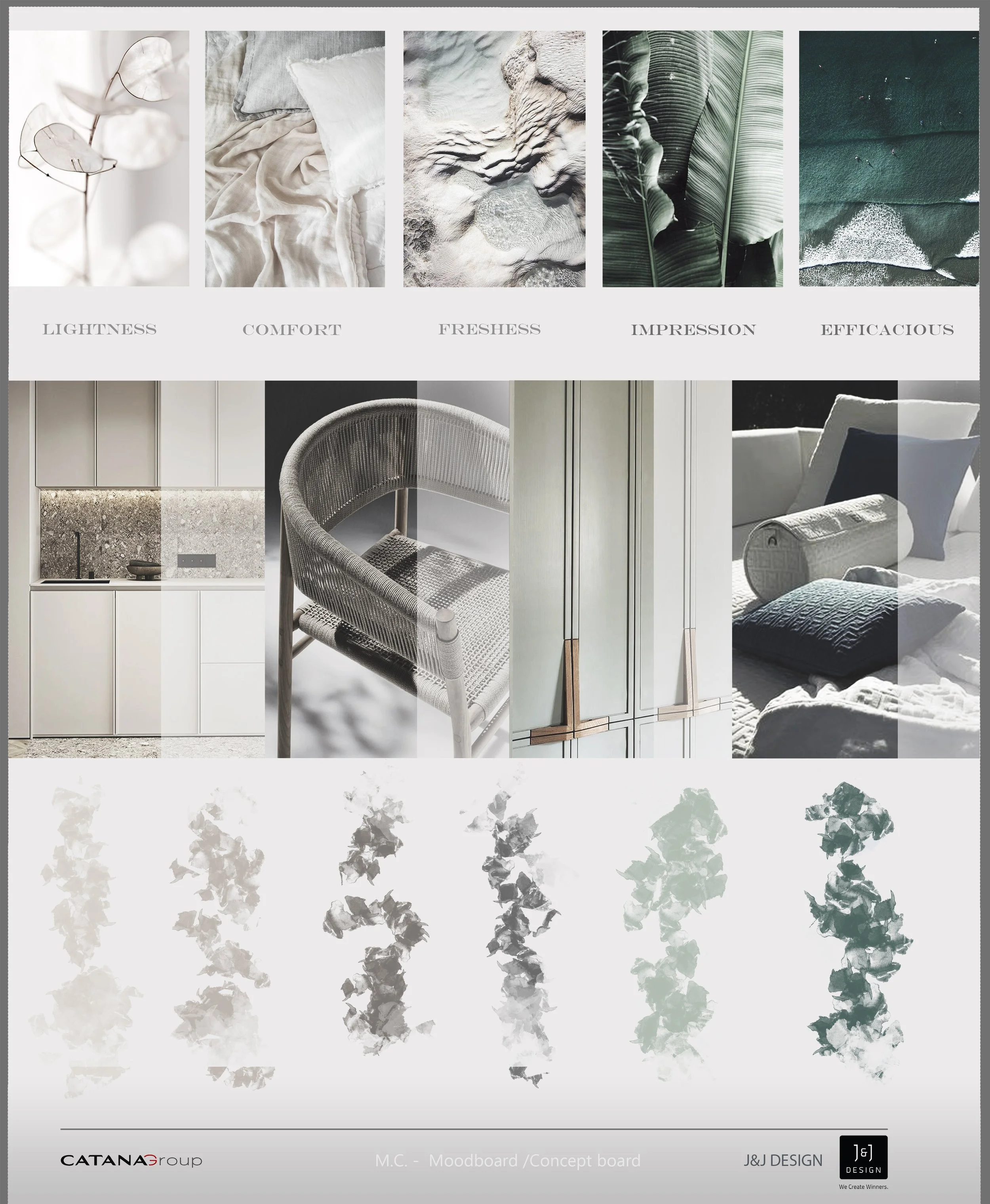

Interior Design and Styling

Based on preliminary general arrangement drawings and sketches the rules of inner design and decor are developed. Materials proposed are chosen, and drawings of typical details, along with a mood board. VR and scale 1 mock-ups are developed as needed. 3D preliminary model is developed to enable the start of the engineering phase. Final 3D models and realistic renders are developed, and as needed modified to develop marketing and sales materials

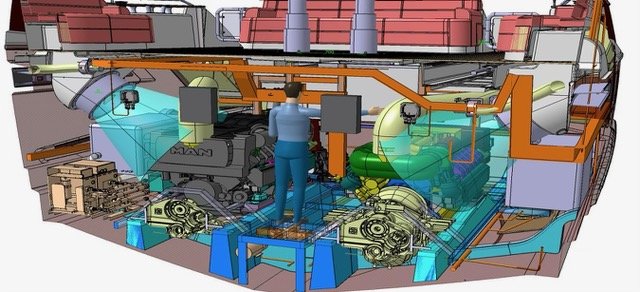

07/

Engineering

Final naval architecture and design drawings, based on the "technical package," support the engineering phase. They provide geometric and technical details of all boat parts and yield a final 3D solid model, typically using Dassault Catia or Siemens NX. Key areas include composite parts (GRP) with final 3D milling files and scantling drawings detailing structural and non-structural components and their calculations. Systems cover propulsion, fuel, steering, electrical, electronics, woodwork, interior appliances, hull/deck gear, hydraulics, water systems, HVAC, safety, and more. The interior design includes engineering for woodwork, upholstery, canvas, curtains, hardware, and related items.

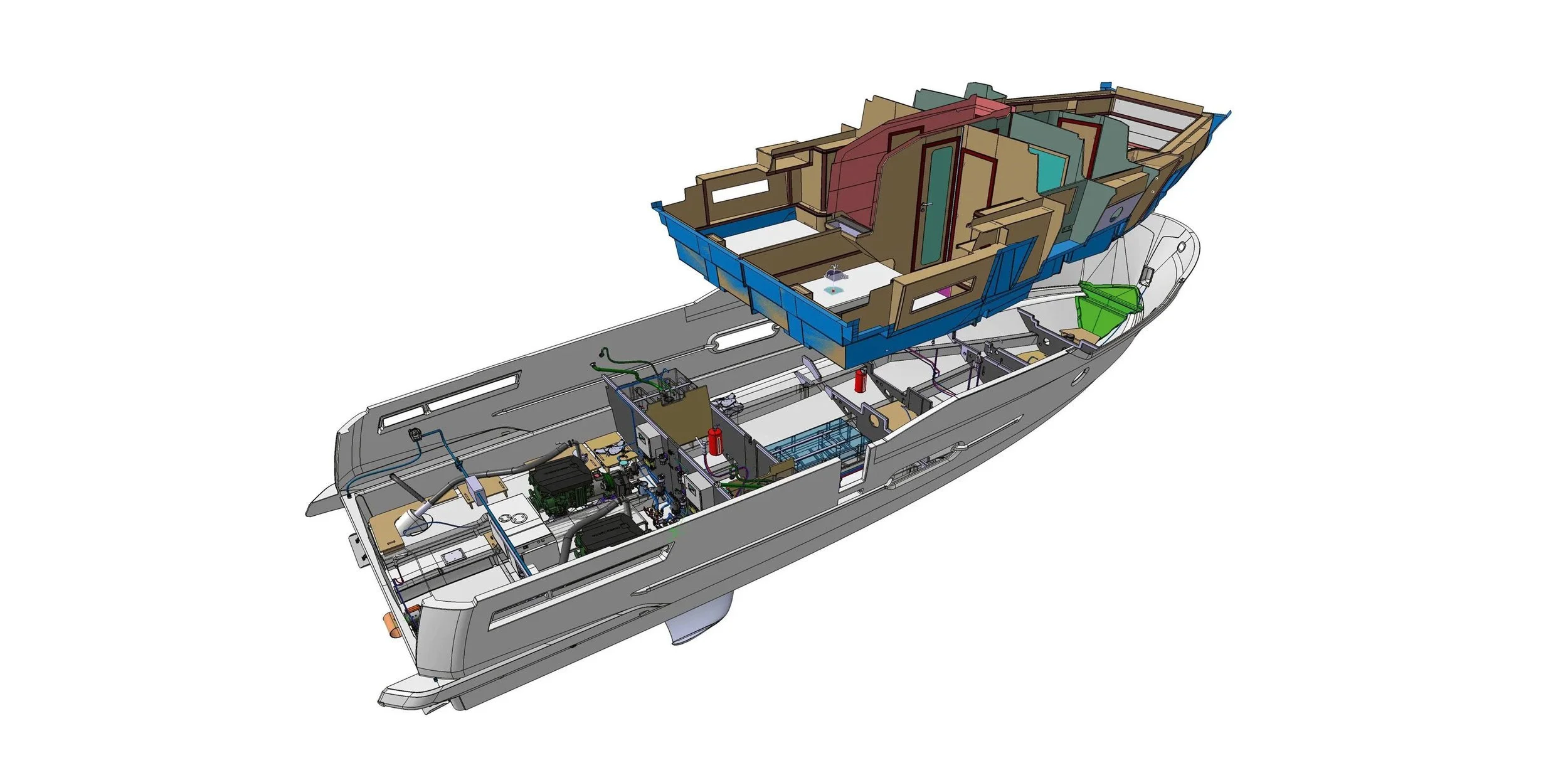

08/

Build Process

Build process must be defined early, because these decisions affect the design, engineering and tooling areas. Will the boat be completely built in-house or will some components be outsourced? Which ones? The composite and assembly production processes are engineered, and the production flows designed. How will the components move inside the factory? Are there any dimensional or weight limitations that need to be respected? Definition of tools and jigs needed, processes, technologies, skills. Value stream analysis. Process times, tack-time, expected volumes, limitations. Definition of ramp-up.

09/

Tooling

Which composite (GRP) technology will be used? Are the ways the GRP production in need of modification or change for this project (injection/infusion, RTM, hand lay-up, post-curing in ovens etc.) and new equipment/investment-training are needed. Adapt tooling to tack time, and manipulation of moulds. When these questions are clear proper custom-designed tooling definition can be made, with definitions of gel coat type, resin/glass structure, reinforcements in steel or other material, mechanical and/or hydraulic open/close or moving mechanisms.

10/

Prototyping/Pre-series

In some cases it is desired that the prototype composite parts are manufactures, and, if needed, the prototype boat 1 is built. This enabled to understand, define and finalise the details of the production and build process, along with building the necessary tools and templates which can only be defined at building boat 1. This build of boat 1 outside the production area is very instrumental in defining well how the production run in the real production area will be running. Sometimes a pre-series of 2 to 5 boats is planned to optimize the smooth production run of the high-volume series.

11/

Testing

Field testing of boat 1 is very important to define what modifications need to be applied to series to able to meet the market in good shape, avoid major design/engineering mishaps and avoid risk of call-back scenarios or major warranty issues. J&J possess a set of dedicated measurements instrumentation and a vast experience in testing of boats in all conditions. Many areas are measured and documented/analysed/compared: speed and consumption vs RPM and load, in different conditions; pitch, yaw and roll analysis; manoeuvre capacity and behaviour; vibration and noise in different areas, etc.

12/

Project Management

Possibly the most important aspect of development project is how it is managed. A smooth flow of cooperation and information between the builder’s and J&J team is needed to achieve best results. The respect of timing and cost (of development and of the final product) must be monitored and controlled during the development process. Typically a project manager on J&J side is working with the project manager on the builder’s side. This manager at some stage of development (at the start of engineering) starts to share all information with the builder’s product launcher. The launcher, typically coming from the production environment, takes over the project at the end of the engineering phase. His job is to finalize the development and prepare a smooth launch in the production area enabling a fast and efficient ramp-up.

13/

AI Assistance

For over forty years, J&J Design has advanced integrated yacht development—uniting naval architecture, engineering, and tooling under one roof. Today, we extend that legacy through artificial intelligence.

Since late 2022, we’ve applied AI to structure large datasets and unlock insights from our 360+ yacht projects. This enabled faster access to validated solutions across structure, naval architecture, BOMs, and build costs.

AI now supports high-fidelity hydrodynamic surrogate models—delivering rapid, accurate performance predictions and real-time design optimization.

Our next step is a proprietary, AI-powered development platform.

This interactive tool will integrate all design phases, enabling:

Faster development cycles

Accurate cost forecasting

Enhanced product quality and value

For our boatbuilding partners, this translates into shorter time-to-market and improved margins.

At J&J, innovation means refining proven methods, not replacing them. AI strengthens our commitment to smart, sustainable yacht design—building on experience, not bypassing it.